CAVA2 works to add value along the cassava value chain through activities which include: improving farm productivity - expanding and improving the efficiency of cassava processing – developing end products and identifying market opportunities. The project’s focus countries are Ghana, Malawi, Nigeria, Tanzania and Uganda.

Marcelo Precoppe, a Crop Postharvest Technologist at the Natural Resources Institute (NRI), is leading a participatory initiative in Ghana designing a new flash (or pneumatic) dryer which is technically appropriate and affordable for smaller scale processing enterprises.

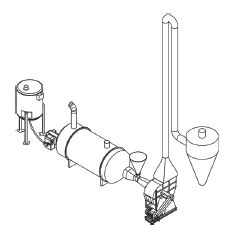

Flash dryers provide good contact between cassava particles and hot dry air, making them the most efficient choice for drying powdered material. However, Ghanaian small-scale cassava processing enterprises currently use flatbed (‘bin’) dryers which have a lower efficiency for this kind of material, or traditional sun drying methods which produce limited volumes. Flash dryers have not been adopted in Ghana, mainly because of their high cost and large-scale capacity. Marcelo is developing a flash dryer suitable for Ghana that involves lower processing capacity compared to the larger Nigerian models and a much reduced cost for the processor. This new smaller, affordable dryer will address a bottleneck in the value-chain and significantly improve profit margins for small enterprises.

Flash dryers provide good contact between cassava particles and hot dry air, making them the most efficient choice for drying powdered material. However, Ghanaian small-scale cassava processing enterprises currently use flatbed (‘bin’) dryers which have a lower efficiency for this kind of material, or traditional sun drying methods which produce limited volumes. Flash dryers have not been adopted in Ghana, mainly because of their high cost and large-scale capacity. Marcelo is developing a flash dryer suitable for Ghana that involves lower processing capacity compared to the larger Nigerian models and a much reduced cost for the processor. This new smaller, affordable dryer will address a bottleneck in the value-chain and significantly improve profit margins for small enterprises.

The project will be delivered collaboratively, with local participation. During his recent trip to Ghana, Marcelo interacted with Homeku Engineering, a local fabricator and Tropical Starch, a local processor, to create a partnership which will design, build and manufacture the new flash dryer in Ghana.

“It’s an exciting engineering challenge and a big step towards improving capacity building for small enterprises. Manufacturing the new dryer in Ghana, will not only benefit local companies and enable maintenance through local suppliers – importantly, it will keep costs down whilst increasing profits for small enterprises”, says Marcelo.

“It’s an exciting engineering challenge and a big step towards improving capacity building for small enterprises. Manufacturing the new dryer in Ghana, will not only benefit local companies and enable maintenance through local suppliers – importantly, it will keep costs down whilst increasing profits for small enterprises”, says Marcelo.

Marcelo will be returning to Ghana in August for four weeks and again in November to support the design, build and assembly of the flash dryer, to troubleshoot where necessary and to train users. The project is scheduled to be completed in the next six months.

For more information contact Marcelo Precoppe.